Fewer passes.

Less compaction.

Better soil health.

Greater profits.

We’ve been busy at Tribine preparing for the next 60 years of no-till.

We’re on a mission to enable better soil health. To make no-till possible in places it’s not today. And to make no-till practices more efficient and profitable.

Imagine planting cover and double crop while harvesting. Conditioning residue and covering compaction tracks in the same pass. Eliminating a grain cart and using less diesel. It can save you harvesting and planting days, help you cover more ground with fewer people, and cut your costs—all in the name of sustainability.

A limited number of Tribines are available for lease for 2022 harvest—including dedicated support. Header and planting innovations will roll out in the coming years.

Featured Video

The TRIBINE Harvester harvesting the 2020 wheat crop.

TRIBINE can unload a full load of grain, over 1000 bushels, in 2 minutes.

TRIBINE hosts Alva Field Day to give farmers a chance to see how it performs.

You can download the TRIBINE Brochure in PDF format at the following link. Right click to download (choose save link as…), or click to open in a new window (browser must support opening PDF files)

Tribine drives farm profitability

by empowering farmers to adopt

no-till practices and reducing harvesting costs

Eliminates two pieces of equipment

Eliminates costs for purchase, maintenance and operation of tractor and grain cart

Decreases labor costs and hassles

One less driver means lower wages and helps solve farm labor shortage

Increases yields

Driving on 35% less of the field means less disruption of seed bed and greater yields

Enables farmers to expand their operation

Harvesting more efficiently means farmers can handle more land with fewer people

Potential to save millions in diesel consumption

By eliminating tractor use for grain carts and deep tilling, Tribine could avoid millions of gallons of diesel consumption in the Midwest

Grain bin and fuel capacity

1000 bushel grain tank

Unload in less than two minutes

Full time all wheel drive

500 gallon fuel capacity. 24 hours continuous operation

Retractable during road use

With a 1000 bushel capacity, Tribine can make multiple field rounds without stopping – and it unloads at over 500 bushels per minute. This unheard of capacity in the industry eliminates the need for tractor and grain cart in many operations.

Tribine requires just two tracks per field pass and has full-time all-wheel drive. The articulated and crab steering makes the Tribine nimble, with a turning circle radius less than most other combines today.

The 500 gallon fuel capacity means Tribine can operate for 24 continuous hours without refueling.

Innovative cab design

Glass cab floor. No steering wheel

Single steering joystick control

360° LED lighting for 24/7 operation

Hinged door and access space

Ladder access in front of tire

Tribine’s innovative cab is designed for operator comfort, intuitive control of the harvester, and unprecedented visibility.

A single steering joystick control replaces the steering wheel for precise maneuverability, and increases operator comfort.

In the steering column area, the glass cab floor provides unrestricted visibility down towards the header and field. The ladder in front of the wheel allows easy access with a spacious walkway for hinged door entry.

Wrapping throughout and around the front edge of the cab, LED lighting enables 24/7 operation, illuminating everything in Tribine’s path. This lighting combines with operator control cameras and the extra large side mirrors, to provide 360 degree operation visibility.

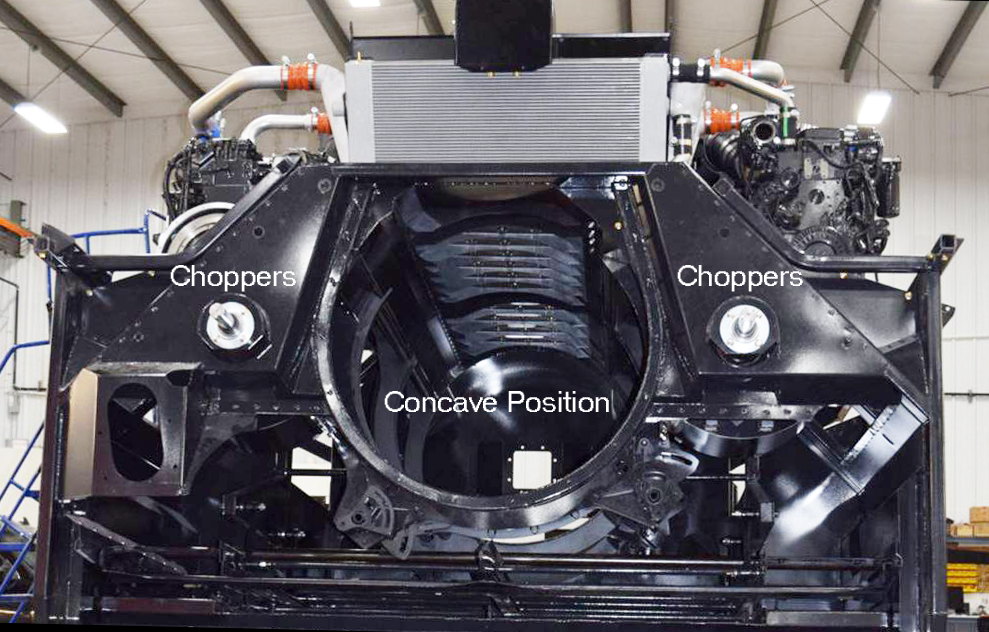

Threshing and cleaning system

Cooling package for both engines

Adjustable transports veins

9 Liter Cummins harvesting engine

9 Liter Cummins propulsion engine

The Tribine carries grain in the rear module, allowing much more room directly behind the cab for a revolutionary new cleaning and threshing system design. The cleaning area is significantly wider than other combines and is assisted by advanced pneumatic methods for removing the chaff from the grain.

The rotor has a swung diameter of 38 inches, and the concave/grate wrap around it is designed to use 270 degree of the cylindrical surface area, providing much larger separation area than other single rotary machines in today’s market.

Feeder drive

Side discharge choppers

Side discharge choppers

103 inch wide cleaning system

270° concaves

38 inch rotor

After the clean grain is separated, two side discharge choppers propel the finely chopped chaff out from the Tribine, for a swath width up to 50 ft. This provides better field distribution of residue, for faster decomposition and return of nutrients back into the soil. Tribine residue management components will finally provide the much needed answer to wide headers and residue problems that go with them, while consuming much less of your harvesting horsepower.

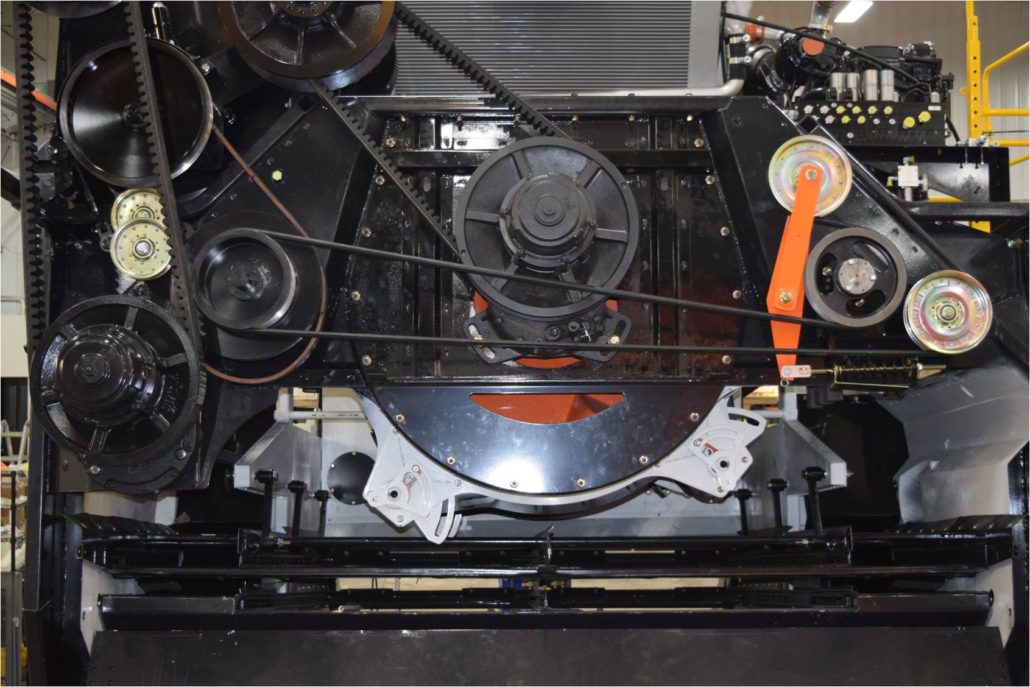

ADJUSTABLE ROTOR VANES

Control the pitch of Tribine’s rotor vanes, hydraulically, from inside the cab. The pitch is adjustable from 0 degrees (slowest) to 27 degrees (fastest). Speed up or slow down the speed that crop passes through the rotor, ON THE GO! Fine tune machine performance to deal with the changes in crops and conditions your operation experiences, throughout the harvest season.

HYDRAULIC CONCAVE ADJUST

Adjust all three banks of concaves with the push of a button. Tribine’s concave adjust system achieves silky smooth operation with rock solid position retention, using a hydraulically actuated cam follower mechanism. The system adjusts the concave clearance from the rotor from fully closed to over 2”. When fully open, the concaves are concentric to the rotor. As the concaves are closed, Tribine’s triple pinch point threshing becomes more pronounced for more aggressive threshing and separating. The power of hydraulics assures that the concaves will not be “frozen” in a given position by time or by crop pressure, should you desire to change the setting.

Watch a video of the inside of the rotor.